Introducing Industry-Leading Drop-and-Hook Innovations

Shippers • Published on November 19, 2020

Today we’re excited to announce enhancements to our drop-and-hook service, Convoy Go, that provide customers with more flexible, reliable capacity, superior service levels, and real-time load visibility. Specifically, we’ve added predictive trailer routing, automated reloads with batched routes, and improved smart trailer telematics to our nationwide drop service.

The challenge with traditional drop-and-hook has been the complexity of matching, tracking, and routing decoupled tractors and trailers. Most carriers and brokers address this problem manually, which often results in stale data and inaccurate forecasting that in turn limits their service to dense lanes with predictable shipments. These traditional drop-and-hook services are often unable to quickly scale to meet unexpected demand surges, forcing shippers to rely on the spot market and live loads, which drive up transportation costs and introduce logistical complications.

Our new capabilities address these pain points and deliver more flexible, reliable, and efficient drop capacity for shippers, with a nearly 100% equipment availability rate, trailers delivered 24 hours before load times, 48% lower dwell times vs. live shipments, deep visibility into every load, and reduced carbon emissions.

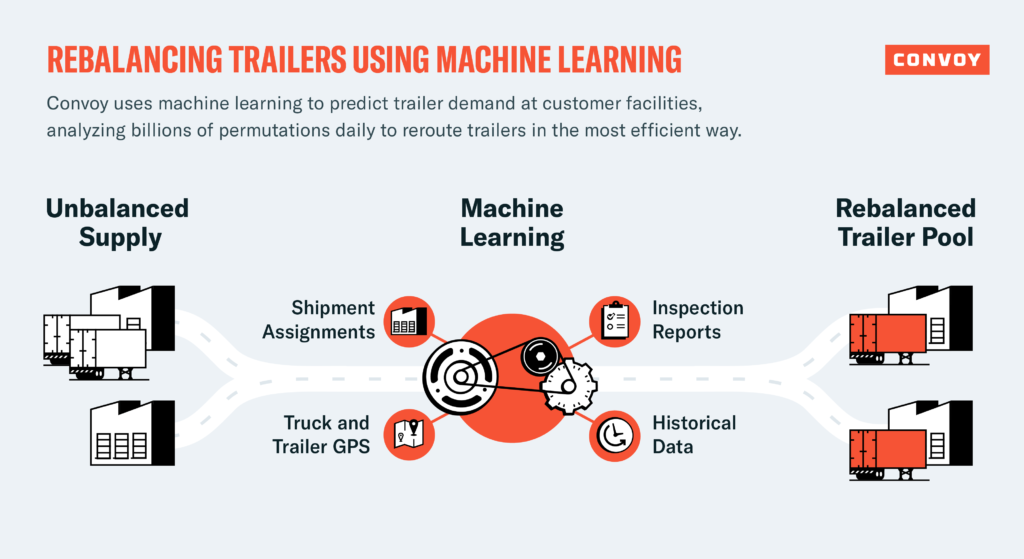

Predictive Trailer Routing

This enhancement proactively routes empty trailers to customers’ facilities, while simultaneously rebalancing our trailer pool. To accomplish this, we use a machine learning model, predicting several weeks in advance how many trailers customers will need across hundreds of facilities nationwide. We combine these forecasts daily with historical shipment data, GPS-based trailer locations, shipment assignments, inspection reports, and driver locations, feeding it all into an optimization model that analyzes billions of trailer route permutations, ultimately picking the most efficient solution.

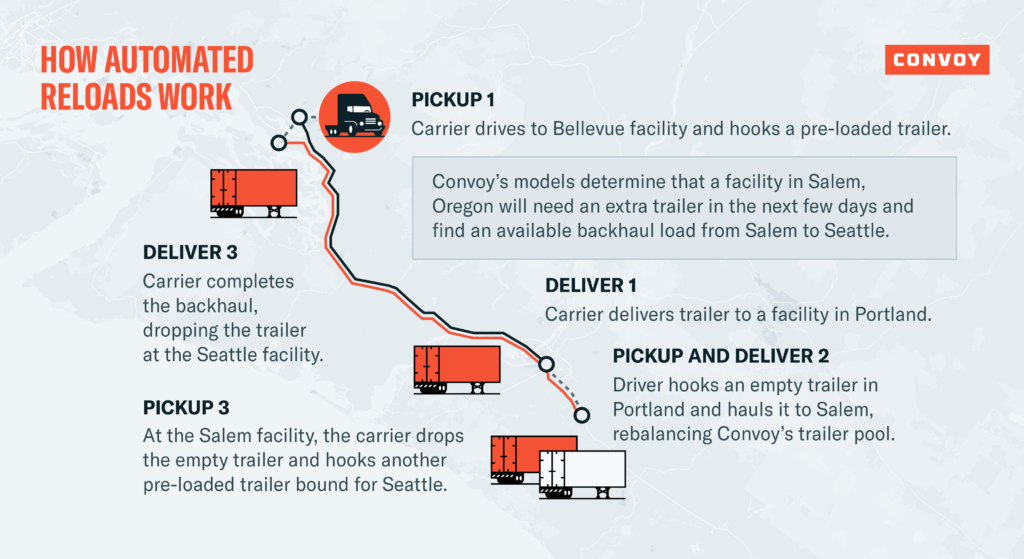

Automated Reloads with Batched Routes

Since we launched automated reloads, which combine headhauls with backhauls, shippers have benefitted from better service due to lower carrier falloff rates, and carriers have earned more through better asset utilization, all while preventing nearly three million pounds of CO2 emissions from entering the atmosphere. Now, automated reloads support batched routes for drop, which combine three or more runs into a single multi-stop job, providing even greater efficiency for carriers and service quality for shippers. In addition, automated reloads can now combine multiple drop and live loads into a single trip, further reducing empty miles and improving asset utilization.

Smarter Trailers, Powered by IoT sensors

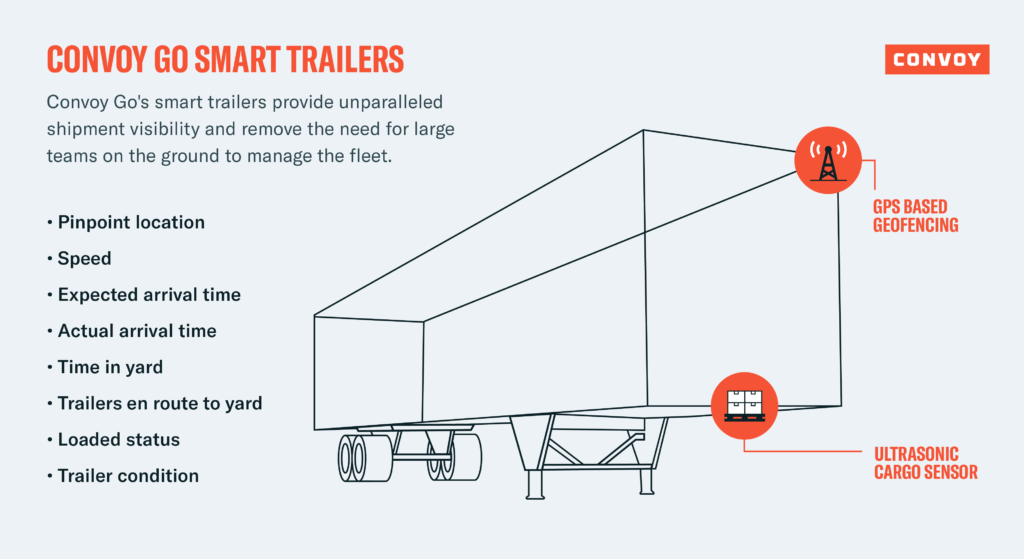

Each trailer in our shared pool is now equipped with advanced telematics, which, combined with Convoy data, provide unmatched visibility into every load. Combinations of ultrasonic, optical laser, and radar sensors deliver real-time information to our cloud-based data lake. A machine learning model then analyzes this data to ensure shipments are progressing as planned, automatically flagging issues that require us to course-correct. As a result, our team and our customers know if trailers are loaded and ready for pickup, if they’re being hauled by the correct driver, if the shipment needs more time, if the trailer is available for another shipment, if a trailer needs preventative maintenance, and how many new trailers are headed inbound to each facility for loading. This automated workflow enables our nationwide fleet of thousands of trailers to be remotely monitored and managed by a handful of specialists, who can make any necessary adjustments even minutes before preloading.

Try Convoy Go Today

Convoy Go is available to any company who ships 250 full truckloads annually on any lane, nationwide. Interested in giving it a try? Learn more by visiting convoy.com/drop-and-hook, or drop us a line at sd@convoy.com. You can also learn more by reading a new white paper we’ve published on the topic, available today for free download.