The next major evolution of drop-and-hook shipments. Announcing Flexible Drop

Data Science • Published on May 19, 2021

Drop shipments offer major advantages relative to Live shipments. With Live shipments, carriers spend an average of 3 hours waiting. Crazy! With Drop, the driver drives into the yard, hooks up a loaded trailer, and drives out in minutes. Up to a third of the cost of truck freight in the US is attributable to time spent waiting for appointments or waiting at the dock to load and unload.

So, why aren’t all shipments Drop? It’s because Drop shipments require that empty trailers are made available ahead of time. That means that shippers have to predict at the beginning of each contract cycle how many shipments they are going to do so that the appropriate number of trailers can be secured. In reality, making accurate predictions every time in advance is impossible given how volatile supply chains are. During any given time period, one shipper will have excess trailers and pay penalties for underutilization while another shipper nearby has a shortage of trailers and has to push loads to live shipments.

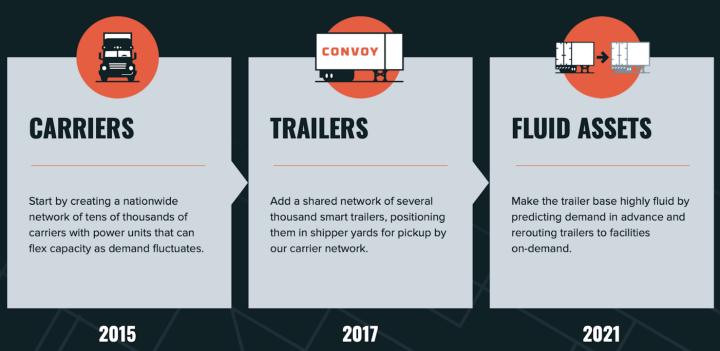

That’s what we set out to change and it has been a long journey. In 2015, we first opened up our app to any carrier giving them instant access to live loads without needing to call brokers. In 2017, we started Convoy Go, piloting drop shipments to figure out how we could give carriers access to the large drop market. Up until then, only asset-based carriers had access to Drop. By 2019, we expanded Convoy Go nationwide and automated much of the matching and pricing.

Today, we are announcing the next evolution of Convoy Go. Our system now in real-time predicts demand and efficiently rebalances trailers across shippers to dramatically increase the ability to do Drop shipments. This means that Drop isn’t just available for a subset of contract freight, but also for backup and spot freight.

Underlying this breakthrough are four major technical innovations:

- Opening up Drop to all carriers — The starting point was expanding drop to any carrier in the US. With Convoy’s large base of carriers that can all do drop, we can quickly bring in new power units as demand patterns shift.

- Smart trailers & remote management — We instrumented every trailer to measure the condition, availability, and status. This lets us understand the true available capacity across our entire trailer fleet.

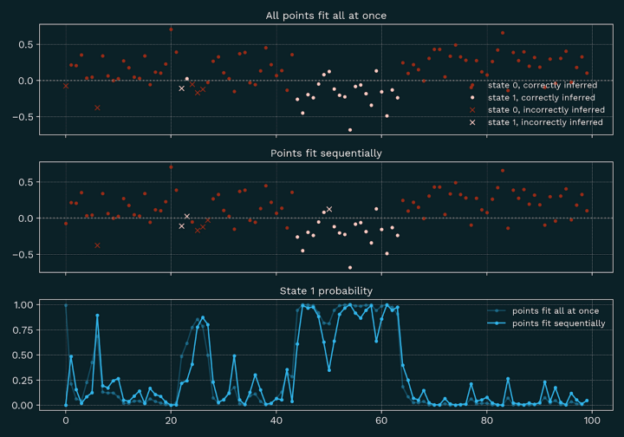

- Demand prediction & automated trailer rebalancing — We built machine learning models that, on an hourly basis, predict trailer demand across facilities nationwide and then automatically determine where the trailers should be moved.

- Automated reloads — We expanded automated reloads to drop loads to ensure that as we are moving both loads and trailers, we get maximum utilization of the trailers and reduce empty miles.

This milestone is an important step on our mission of “Endless Capacity and Zero Waste“, but we know we are still early in the journey.