Case study: Lowering TONU costs with supply chain analytics

Industry Insights, Shippers • Published on December 3, 2020

Part 1 of our case study showed how Convoy’s digital freight network provided flexible capacity for a customer when demand surged past supply chain forecasts. In part 2, we’ll explore how supply chain analytics uncovered hidden TONU (truck ordered, not used) costs, providing this customer with savings opportunities.

Supply chain analytics with a digital freight network

Convoy’s digital freight network collects more than 1,000 data points on every shipment. We have a stack of automated tools and a team of data scientists that analyze this supply chain data to provide network insights. We provide detailed visibility into our customers’ freight operations, helping them make informed decisions when it comes to transportation and logistics.

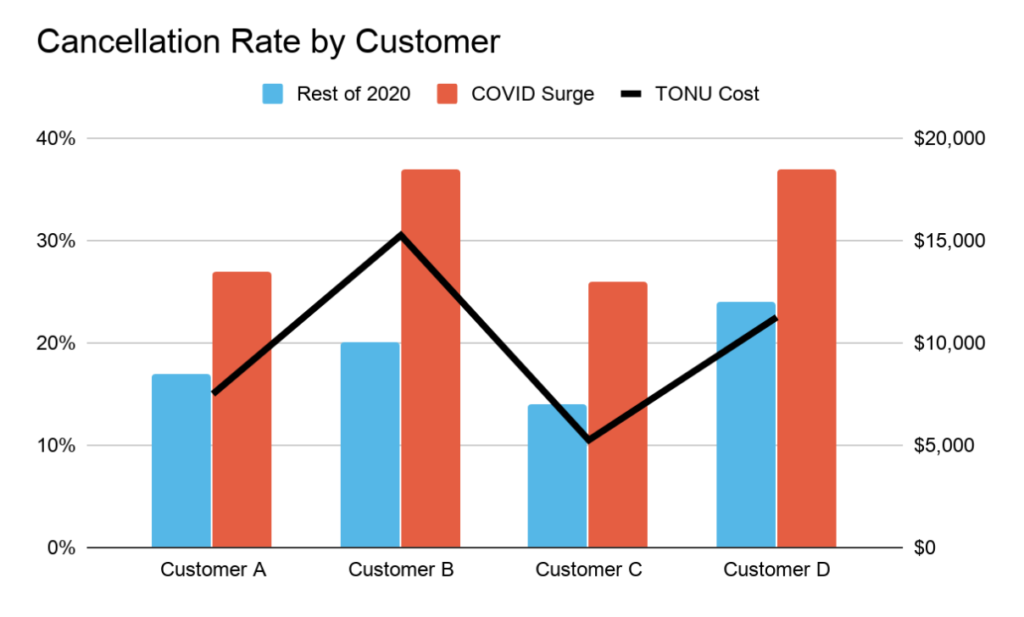

In the case of our food and beverage shipper handling COVID-19 freight surges, we applied our data and insights to understand how customer behavior impacted their bottom line. The COVID-19 panic explained why the shipper’s customers placed so many short-notice orders, but when investigating more closely, we saw that this group of orders had an above-average percentage of cancellations–over 10% higher than average.

We evaluated the root cause of this surge in cancellations and the impact to the shipper’s bottom line.

Uncovering cancellations and TONU charges

Our analysis revealed that, in times of volatility, grocers and supermarkets are likely to over-order to ensure they secure enough product to stock their shelves, then cancel excess shipments when they overestimate demand. While this may be a prudent strategy for their customers, cancelled shipments are a huge problem for shippers because they create the same operational burden but generate no revenue. Canceled orders can bring additional costs in the event that TONUs are required.

Unfortunately, without data to back it up, shippers often struggle to recoup appropriate compensation for the costs associated with cancelled shipments. This is where Convoy’s network insights came in.

Convoy found that over $35K in TONU charges were incurred as a result of these cancellations. We proactively prepared a report detailing the impact of the cancellations, which customers accounted for the most cancellations, and which of them led to TONU charges. Using these insights, we recommended that our shipper use this information to recoup TONU charges or to negotiate for terms that better reflect the true nature of their customer relationships in future contracts.

While our customer was already aware that they had canceled orders, we found that our data better equipped them to understand the scope of their TONU charges and improved their negotiating position to recoup costs. There are many hidden costs associated with transportation beyond the price per shipment on a given tender, and supply chain visibility can uncover new ways to save on freight.

Gaining a complete view of transportation costs with supply chain analytics

The best part is that we do this all free of charge. At Convoy, we envision a new kind of freight partnership, one that is focused on the long term with a deep appreciation for the fact that we succeed when our customers succeed. We work on behalf of the shippers we work with to analyze supply chain operations, quantify business impacts, and offer new perspectives on how to meet transportation goals.

When you choose to work with Convoy for your freight needs, we will take every opportunity to help solve problems in your supply chain as proactively as you do. If this sounds like the type of freight partner you’re looking for, we’d like to start a conversation. Contact us and a member of our team will reach out to learn more about your specific needs.

Or if you’re interested in learning more about the types of insights that Convoy could provide, check out our latest white paper, Supply Chain Visibility and the Digital Freight Network.